PVC – Advancing Safety and Sustainability in Healthcare

For over 70 years, polyvinyl chloride (PVC) has been at the forefront of medical innovation, providing safe, reliable solutions for screening, diagnosis, treatment, and patient care. Vinyl, another term for PVC, offers unmatched durability, chemical resistance, and cost efficiency, making it the preferred choice for medical devices, as well as flooring, wall coverings, and other vital components of hygienic healthcare environments. PVC's evolving sustainability ensures it remains a trusted material for modern healthcare needs

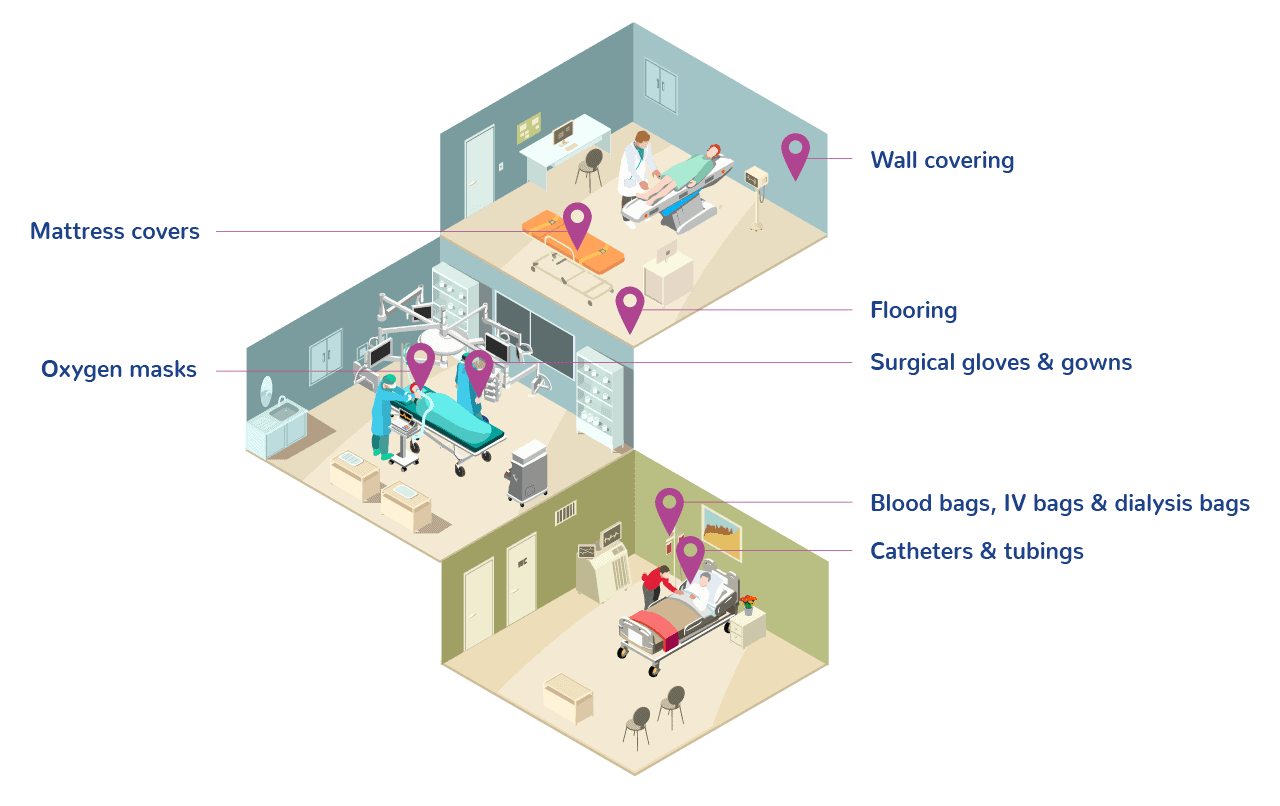

Discover PVC in healthcare

Why PVC should remain the preferred material in healthcare

In response to the latest papers and critiques from NGOs on PVC, the PVCMed Alliance has proactively undertaken the task of providing an updated perspective on PVC, grounded in the most recent and relevant evidence. This critical review of the NGOs' approach to PVC aims to offer a balanced and fact-based view of PVC's role and impact in healthcare.

News

Sign up for our newsletter

Where is PVC used in healthcare?

About us

PVCMed Alliance is The European Council of Vinyl Manufacturers' value chain platform to raise awareness and promote informed decisions about the use of PVC in healthcare. The Alliance was established in 2012.

Our vision

The vision that informs the PVCMed Alliance’s work is of a healthcare environment that best benefits patients and healthcare professionals. Such an environment offers the finest PVC-based products and applications with the required properties and excellence needed to provide top quality health care while being environmentally sustainable.

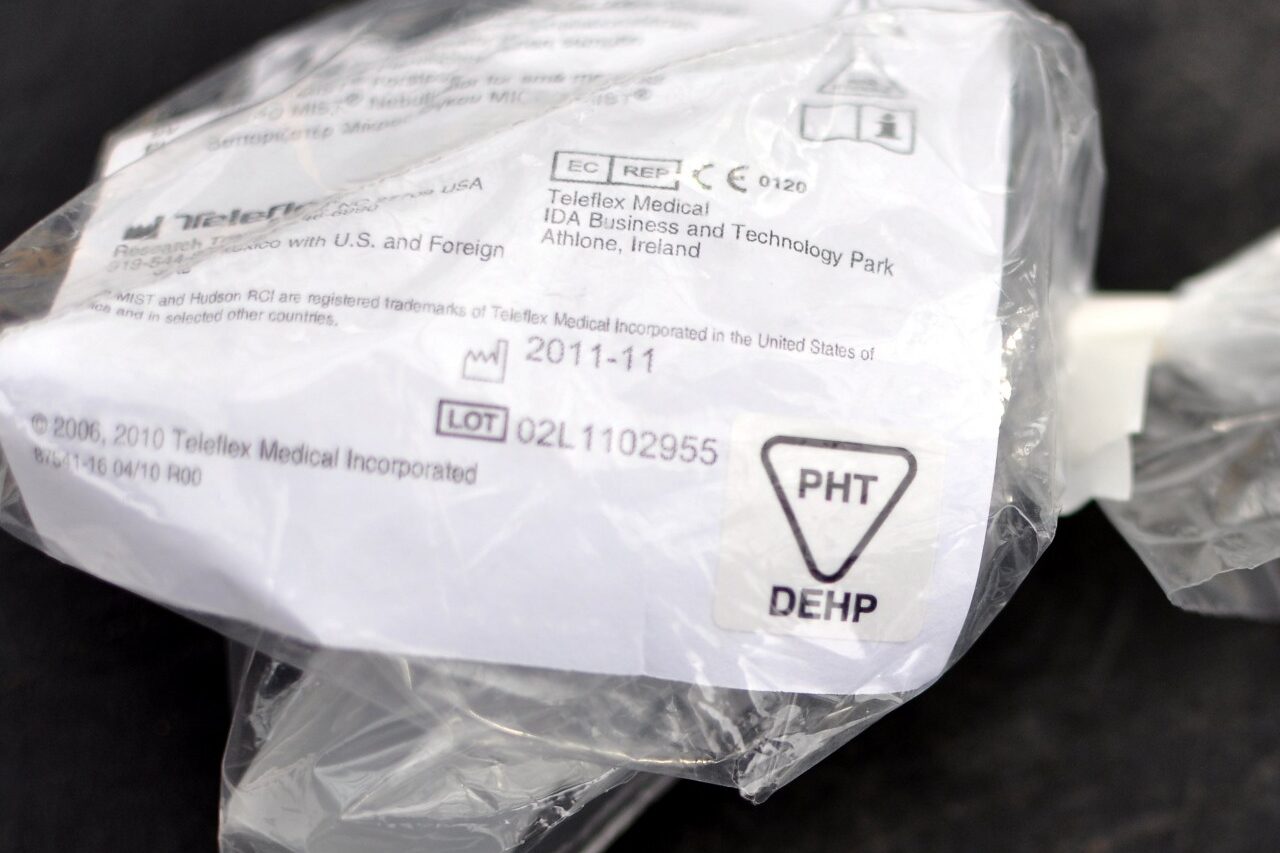

PVC to remain the most used plastic for medical devices

Almost 30% of the plastics-based medical devices are manufactured in PVC, which makes the material the most used polymer for bags, tubing, masks and other disposable medical devices. Due to the material's unique properties, this share is expected to remain the same until at least 2027.

PVC recycling in hospitals

Hospitals use a lot of single-use PVC-based medical devices every day. Besides being safe and affordable, PVC is easily recyclable and keeps its technical properties through numerous recycling cycles. Also, many of the devices are used on non-infectious patients. These advantages have led to the set-up of medical devices recycling systems, such as VinylPlus® Med in Belgium.

When plastics revolutionised healthcare

Did you know PVC-based medical devices have been used safely for over 70 years?

Today, plastics is the primary choice for disposable medical devices, allowing patients and healthcare professionals to benefit from the material’s excellent technical properties on a daily basis. But in fact, it is only quite recently that plastics have replaced medical devices made of metal, glass and ceramics.