For over 70 years, PVC medical devices have allowed patients and healthcare professionals to access an ever-widening range of healthcare applications for screening, diagnosis, treatment and care, with optimal technical performance, safety and comfort in use.

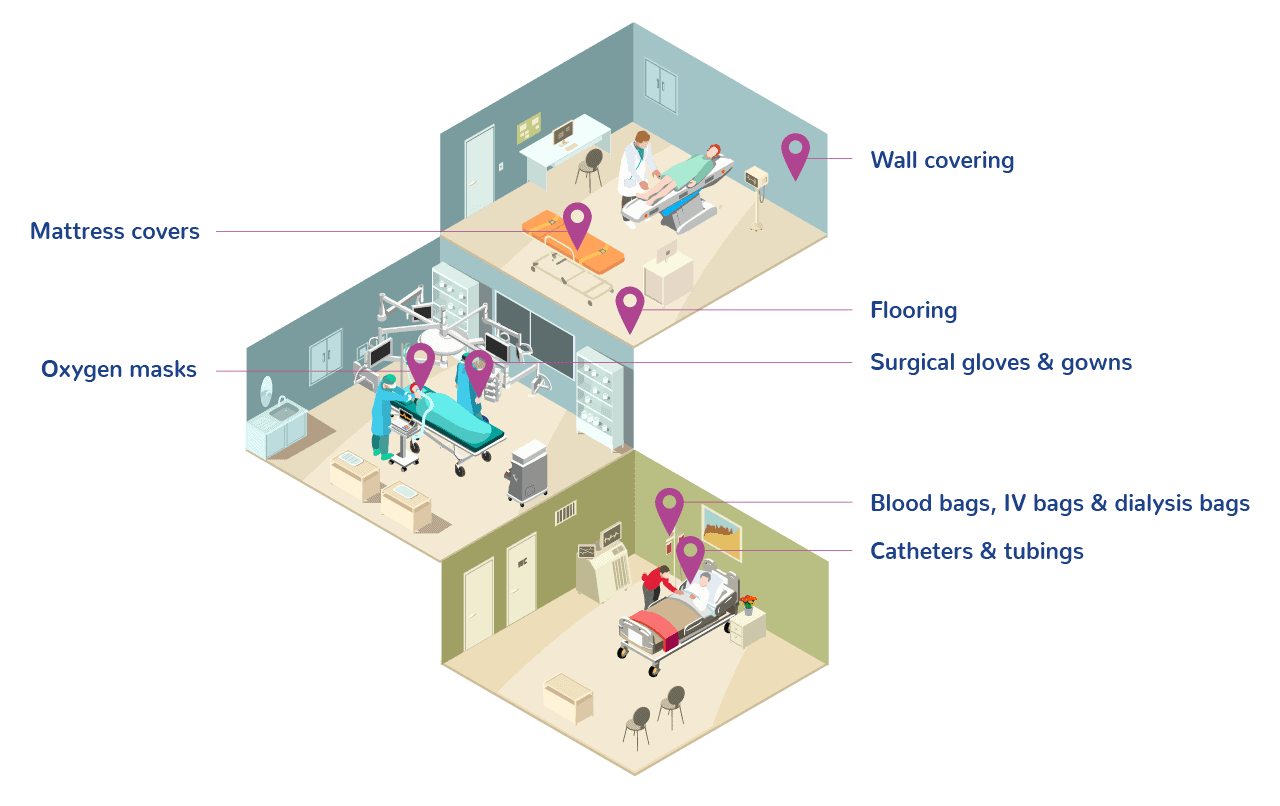

Vinyl (another word for PVC) offers excellent durability, chemical resistance, low maintenance costs and affordability, which have made the plastic material a top choice when it comes to flooring, wall covering and other key elements of hygienic healthcare facilities.

Thanks to these features, the polymer is the single most used polymer for plastics-based medical devices used in hospitals. As one of the most versatile materials available, vinyl is also used extensively in the healthcare sector for cables for telecommunications, pipes for drinking water and sewage, energy-saving windows and a range of other products.

Where is PVC Used in Healthcare?

Applications of Medical PVC

PVC is used in a wide variety of medical devices and other healthcare applications. Discover some of them here:

Medical Tubing

Breathing & Ventilation

Catheters

Dialysis

Diagnostic & Treatment Equipment

Surgical & Patient Safety Supplies

Patient Comfort, Rehabilitation & Mobility

Medicines Development & Production

DEHP-Free Plasticisers Available for Medical Applications

In order to make the PVC material soft and flexible, plasticisers (US: plasticizers) are added. As all medical devices, PVC medical equipment with any plasticiser is subject to stringent pre- and post-market control and evaluation procedures to ensure safety and performance. A wide range of plasticisers are now included in the European Pharmacopoeia, which sets Europe’s legal and scientific standards to delivering high quality medicines in Europe and beyond.

10 Key Reasons to Choose PVC in Healthcare Applications

PVC medical devices are recyclable

Besides being a safe, reliable and cost-efficient material for healthcare delivery, polyvinyl chloride (PVC) plastic is also particularly well-suited for mechanical recycling. This is due to the polymer's unique molecular structure, which allows for the formulation of products varying in rigidity and flexibility and enables PVC to maintain its structural integrity and strength through multiple recycling processes. Medical products labelled 'PVC-free' are often made from multiple layers of different polymers, complicating mechanical recycling.

Thousands of tonnes of medical plastic waste is generated daily at hospitals and healthcare facilities around the world. Studies show that only a small fraction of the waste is hazardous, which means the potential for circular economy in healthcare is huge. Moreover, medical PVC is a high grade material that is sought after by recyclers and can be recycled into a wide variety of new products.

By collecting waste for recycling instead of sending it to costly waste incineration or landfill, hospitals save money. These advantages have led to the set up of recycling schemes for PVC medical devices in Belgium, Australia, New Zealand, South Africa, and elsewhere.

PVC enabled a revolution in healthcare

PVC medical devices were originally developed as replacements for natural rubber, glass and metal. Medical devices made of these materials required cleaning and re-sterilisation before reuse. The safety, high performance, low cost and versatility of PVC made it possible to manufacture single-use medical devices.

In the early 1960s, this resulted in a revolution within the healthcare sector. PVC medical applications can be easily sterilised while keeping their key properties such as flexibility and resistance to tears, scratches and kinks. PVC-based medical devices thus improved medical safety dramatically by reducing the risk of life-threatening and healthcare-acquired infections caused by traditional, multiple-use medical devices.