Plastics have paved the way for many medical breakthroughs since they were introduced after World Word II. Many different polymers are used in healthcare, but polyvinyl chloride, also known as PVC or vinyl, is the single most used plastic with a market share of nearly 30%. Why is it that PVC has become the polymer of choice for medical devices, flooring, wall covering, and a range of other products used in hospitals, clinics, and other healthcare facilities?

Did you know PVC was discovered more than 100 years ago?

Polyvinyl chloride, also known as PVC or vinyl, is one of the oldest plastics. The story of PVC begins in the 19th century with two accidental discoveries. In 1838, French physicist and chemist Henri Victor Regnault, and later in 1872, German chemist Eugen Baumann, observed the formation of a white solid within flasks containing vinyl chloride gas exposed to sunlight. This early form of PVC, however, proved difficult to manipulate and its commercial potential remained unexplored.

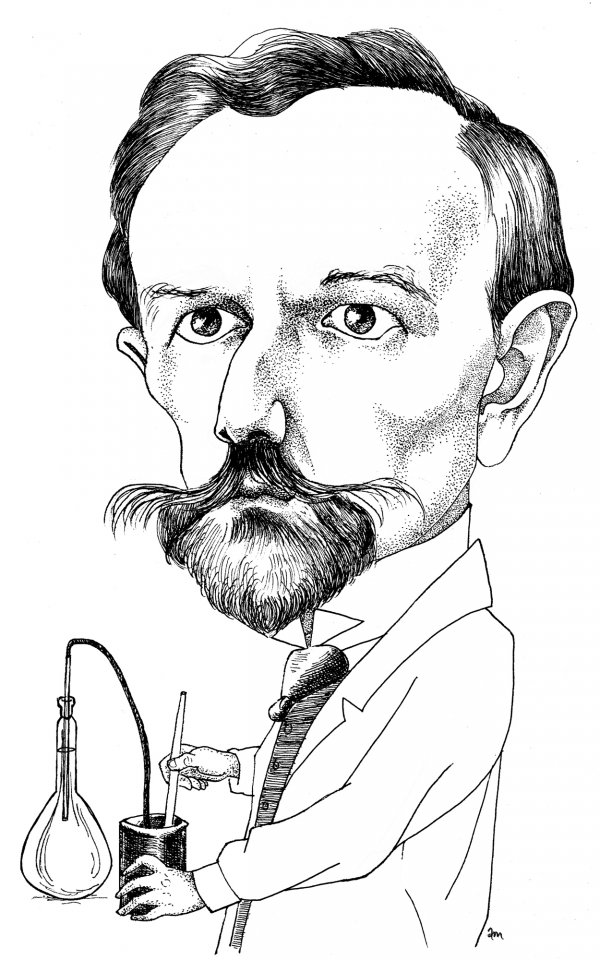

It wasn't until 1913 that German inventor Friedrich Heinrich August Klatte (pictured on the right) patented a method for producing PVC, using sunlight to polymerise vinyl chloride. Yet, the real breakthrough came in the United States when BFGoodrich hired industrial scientist Waldo Semon. Tasked with finding a synthetic alternative to natural rubber, Semon's experiments led to the production of plasticised polyvinyl chloride. The first PVC water pipes were installed in Germany in the 1930s, many of which are still in use. In the medical field, PVC's first was the blood bag, invented in the 1950s.

Since then, PVC has remained the polymer of choice for an ever expanding array of life-saving medical applications that are safe, reliable and affordable.