COVID-19 has highlighted the crucial role played by single-use plastic medical devices in the prevention and control of infection in hospitals. The dramatic increase in the need of disposable devices has shed light on the challenges of properly managing and discarding them after use. Proper sorting and recycling of non-infectious plastic waste can both significantly reduce hospitals' environmental impact and waste management costs.

PVC is the single most used polymer for disposable medical equipment such as oxygen and anaesthetic masks, tubing, IV and dialysis bags. Besides being safe and affordable, PVC is easily recyclable and keeps its technical properties through numerous recycling cycles. Also, many of the devices are used on non-infectious patients. These advantages have led to the set-up of medical devices recycling systems in the healthcare sector.

VinylPlus® Med accelerates sustainability in European healthcare

In 2022, VinylPlus launched the partnership VinylPlus® Med. Aimed at accelerating sustainability in European healthcare through the recycling of discarded single-use PVC medical devices, the project brings together hospitals, waste managers, recyclers and the PVC industry.

High value recyclate

Only clean and REACH-compliant PVC waste is recycled. To ensure that only DEHP-free is reprocessed, a near infrared scanner has been developed that is able to detect PVC and DEHP. The waste can be recycled into a wide range of value products marketed across Europe, for instance durable wall covering for hospitals. Belgium is chosen as pilot country. Additional pilot programmes are underway in other European countries.

A growing network

Interest for VinylPlus Med is growing in the Belgian healthcare community. More and more hospitals are joining the pilot programme where experts teach staff about correct sorting for recycling. VinylPlus Med is also active at healthcare sustainability events around Belgium.

hospitals collect PVC medical devices

hospitals on waiting list

waste management locations

plastic recycler

From medical tubing to hospital wall covering

The medical PVC waste collected at VinylPlus Med hospitals can be turned into a wide range of useful products to be used in the health sector. An example is vinyl wall covering, which can incorporate recycled PVC. Vinyl wall covering is hygienic, dimensionally stable and resistant to chemicals. Due to its durability and shock-absorbent properties, vinyl is ideal for walls which have to be protected from collisions with beds and other types of hospital equipment. Vinyl also helps to create a holistic architectural design expression.

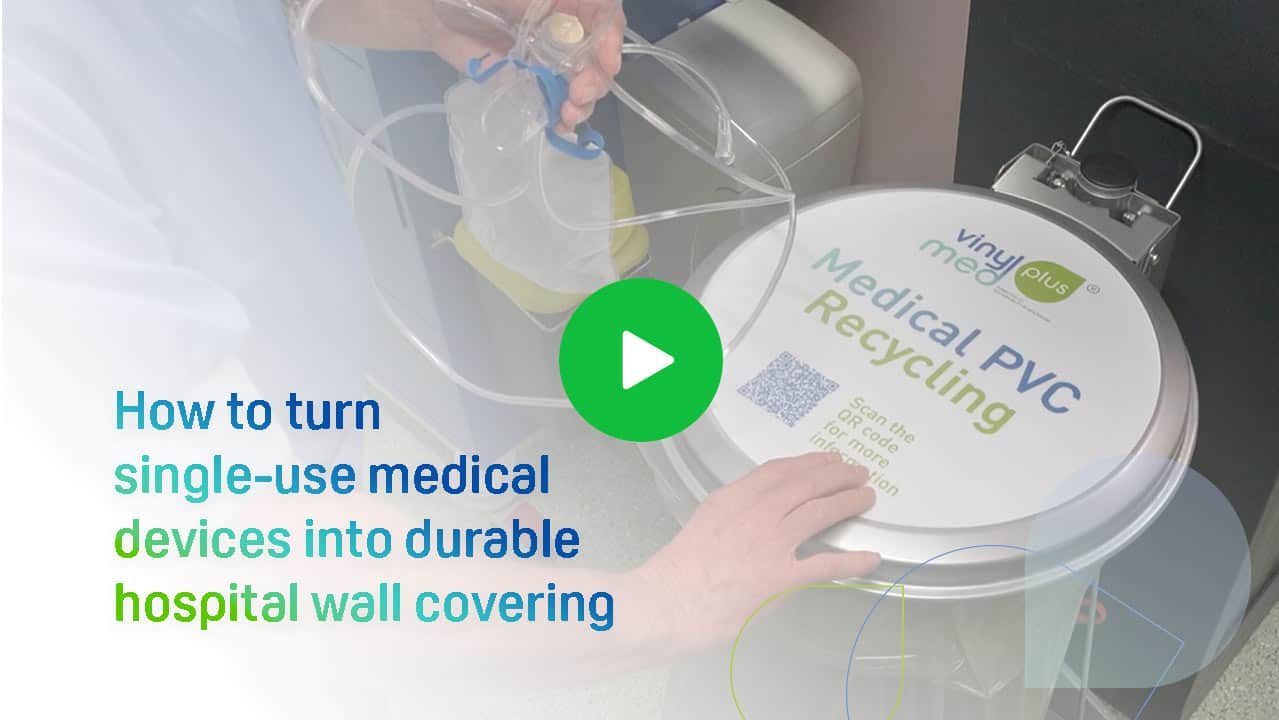

Recycling PVC medical tubing cuts greenhouse gas emissions by 25% compared to incineration

To quantify the carbon savings achieved through VinylPlus Med’s recycling efforts, French consultancy Ecovamed conducted a Life Cycle Assessment (LCA) on PVC-based medical tubing in Europe. This evaluation estimated the carbon footprint from start to end, adhering to the GHG Protocol standard, and analysed two scenarios for the tubing’s end-of-life:

- Incineration with energy recovery and acid flue gas treatment

- Recycling of medical tubing by mechanical grinding in Belgium, with an 80% yield, and production of wall coverings with the recycled material

On a cradle-to-grave basis, recycling allows to reduce by 25% the greenhouse gas emissions of a PVC medical tubing on its full life cycle, as compared to the scenario with incineration, corresponding to 2.0 kg CO2eq avoided per kg of tubing.

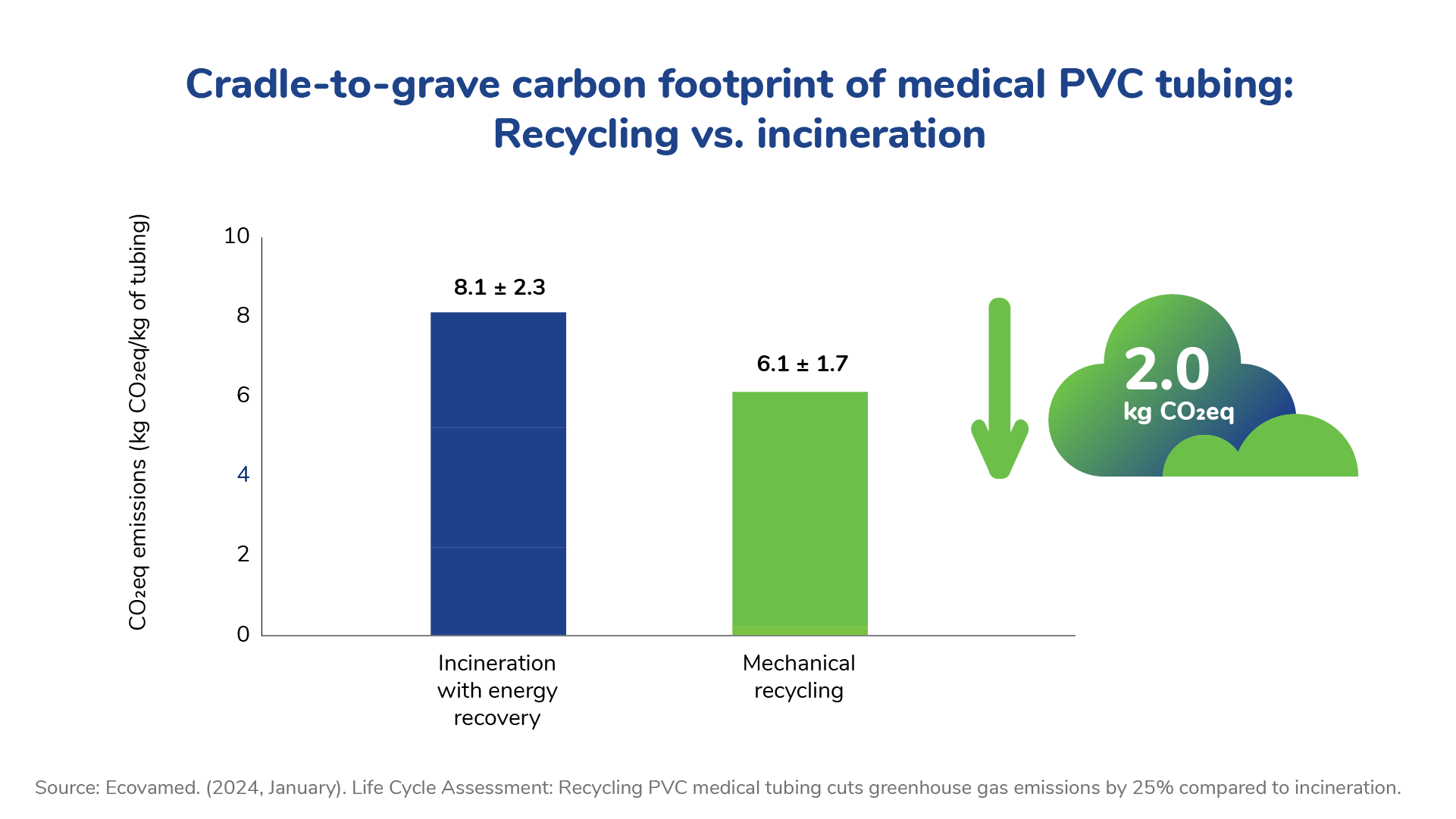

6,200 tons of plasticised PVC being used each year in Europe to produce medical tubing. The annual greenhouse gas avoided emissions if all medical tubing would be recycled are 13,165 tonnes CO2eq emissions, which is equivalent to 7,438 back and forth flights for 1 passenger between Paris and New York.

Discover other PVC medical recycling programmes from around the world

In Australia and New Zealand, more than 200 hospitals collect IV bags, face masks and oxygen tubing for recycling. The scheme is run by the Vinyl Council of Australia with support from medical device manufacturer Baxter. The recyclate, which is of high-grade quality, is used to manufacture mats, hoses and other useful products.

In a pilot, medical device manufacturer Baxter and Northwestern Medicine successfully diverted six tonnes of PVC IV bags from landfill. The pilot is now being expanded to increase scalability.

In South Africa, PVC IV bags are recycled into school shoes for disadvantaged children. Only 20 IV bags are needed for a pair of shoes. Because the shoes are made entirely of PVC, they are 100% recyclable. When the shoes get too small for the kids, they hand them over for recycling and then get a new pair of appropriate size. The programme has helped to incubate new small businesses.

In September 2020 the Vinyl Institute of Canada and Environment and Climate Change Canada launched the PVC 123 pilot programme for PVC oxygen delivery devices, PVC oxygen tubing, PVC fluid bags/containers.

About 25 hospitals in Guatamala collect used PVC medical devices for recycling. The PVC is recycled into shoes that are distributed to school children in Guatemala City. The shoes are handmade by indigenous Kekchis women, which provides jobs and income to this minority group.

In Colombia, PVC used in dialysis clinics and home dialysis patients are collected. Through collaboration with local organisations, the waste is recycled into chairs, water hoses and other applications.

In Thailand, PVC dialysis bags are being collected and recycled. It started with one hospital in 2015 and has now expanded to cover several hospitals. Work is ongoing to make the programme national.

Which products are typically recycled?

PVC is used for a wide range of medical equipment. Here are some of the products that are typically recycled in existing recycling schemes:

Oxygen & anaesthetic masks

Oxygen tubing

Dialysis bags

IV bags

Why recycle medical devices?

The potential for medical device recycling is huge, as studies show that only a small fraction of the medical plastic waste is infectious. By recycling medical devices both hospitals and the environment win:

Cost savings for hospitals

CO2 savings

Energy savings

Safe collection & recycling

High grade recyclate