Plastics, especially PVC, frequently find themselves at the center of environmental discussions. Given PVC's controversial reputation, it's understandable that NGOs and other stakeholders often voice their concerns and opinions about this widely used material.

In response to the latest papers and critiques from NGOs on PVC, the PVCMed Alliance has proactively undertaken the task of providing an updated perspective on PVC, grounded in the most recent and relevant evidence. This critical review of the NGOs' approach to PVC aims to offer a balanced and fact-based view of PVC's role and impact.

Key points

European Chemicals Agency Affirms Safe European PVC Production

Regulation and Safety of Plasticisers:

Stringent Regulations and Safety Measures

DEHP Alternatives in Medical Devices

Chlor-Alkali Industry’s Vital Role

Safe PVC Disposal and Recycling

Advancements in Chlorine Production

Complexity of Phasing Out PVC

Energy Efficiency of PVC

DEHP-Free PVC Blood Bags

MARKET STUDY

Recyclable PVC to remain the most used plastic for medical devices

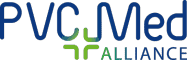

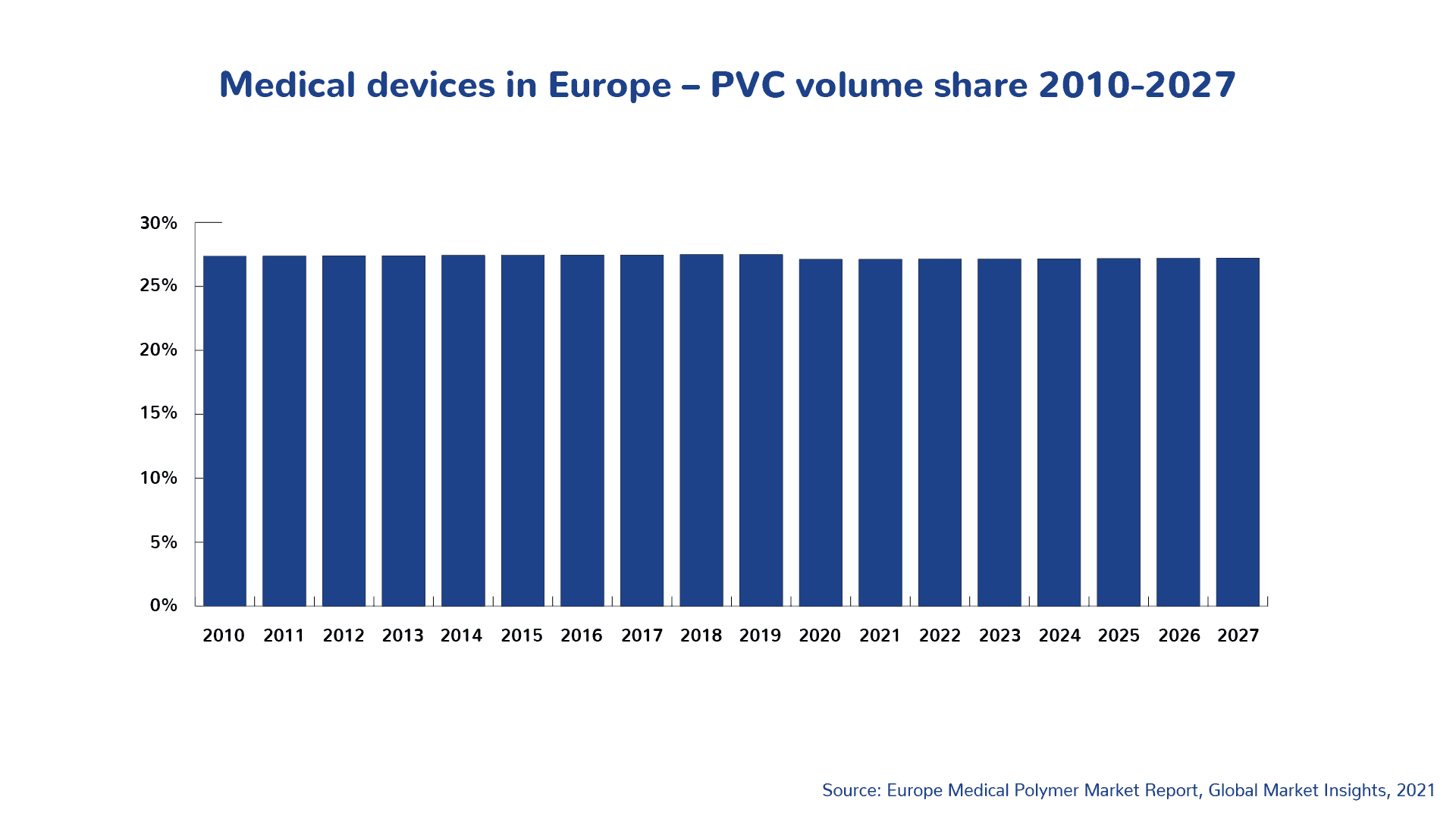

Almost 30% of the plastics-based medical devices are manufactured in PVC, which makes the material the most used polymer for bags, tubing, masks and other disposable medical devices. Due to the material's unique properties, this share is expected to remain the same until at least 2027.

Sign up for our newsletter

The European PVC industry's sustainable development journey continues

During the last two decades the production, use and waste management of PVC in Europe have undergone a significant transformation. Through VinylPlus, the European PVC industry’s Voluntary Commitment to sustainable development, problematic additives have been substituted, recycling systems have been set up and emissions from raw material production are now controlled.

VinylPlus 2030 is the next 10-year Commitment of the European PVC industry to Sustainable Development. With its renewed Commitment, VinylPlus aims to contribute proactively to addressing the global sustainability challenges and priorities.

The VinylPlus 2030 Commitment has been developed bottom-up through industry workshops and with an open process of stakeholder consultation. Three ‘Pathways’ and 12 ‘Action Areas’ have been identified embracing the PVC value chain’s circularity, its advancement towards carbon neutrality, minimisation of the environmental footprint of the PVC production and products, and its engagement with stakeholders and global coalitions.