Polyvinyl chloride, known as PVC or vinyl, contributes to all three pillars of sustainability, not least in healthcare. The material is made from 57% chlorine derived from common salt, an abundant resource, and only 43% fossil feedstock. Bio-based, ISCC PLUS-certified PVC compounds are also available.

PVC is easily recyclable and take back schemes for PVC medical devices are in place in several countries: Throughout Belgium, the United States, Australia, New Zealand, and several other countries more than 300 hospitals collect PVC medical devices from non-infectious patients for recycling into useful products.

The economic and social pillars of sustainability are fulfilled as well: As it is a very affordable material, PVC has helped enable access to quality healthcare for the broader population. According to the European Commission, a switch to alternative materials could increase costs for medical devices by 30%, thereby putting further stress on already increasing healthcare costs in Europe and beyond.1European Commission, Directorate-General for Environment, (2022). The use of PVC (poly vinyl chloride) in the context of a non-toxic environment : final report, Publications Office of the European Union. https://data.europa.eu/doi/10.2779/375357. p. 296

Medical PVC's contribution to the Sustainable Development Goals

PVC or vinyl has a direct contribution to several of the SDGs and has an enabling effect on others. Below are a few examples.

SDG 3: Good Health and Wall-Being

SDG 12: Responsible Consumption and Production

SDG 13: Climate Action

SDG 17: Partnerships for the Goals

VinylPlus – a united PVC value chain committed to sustainable development

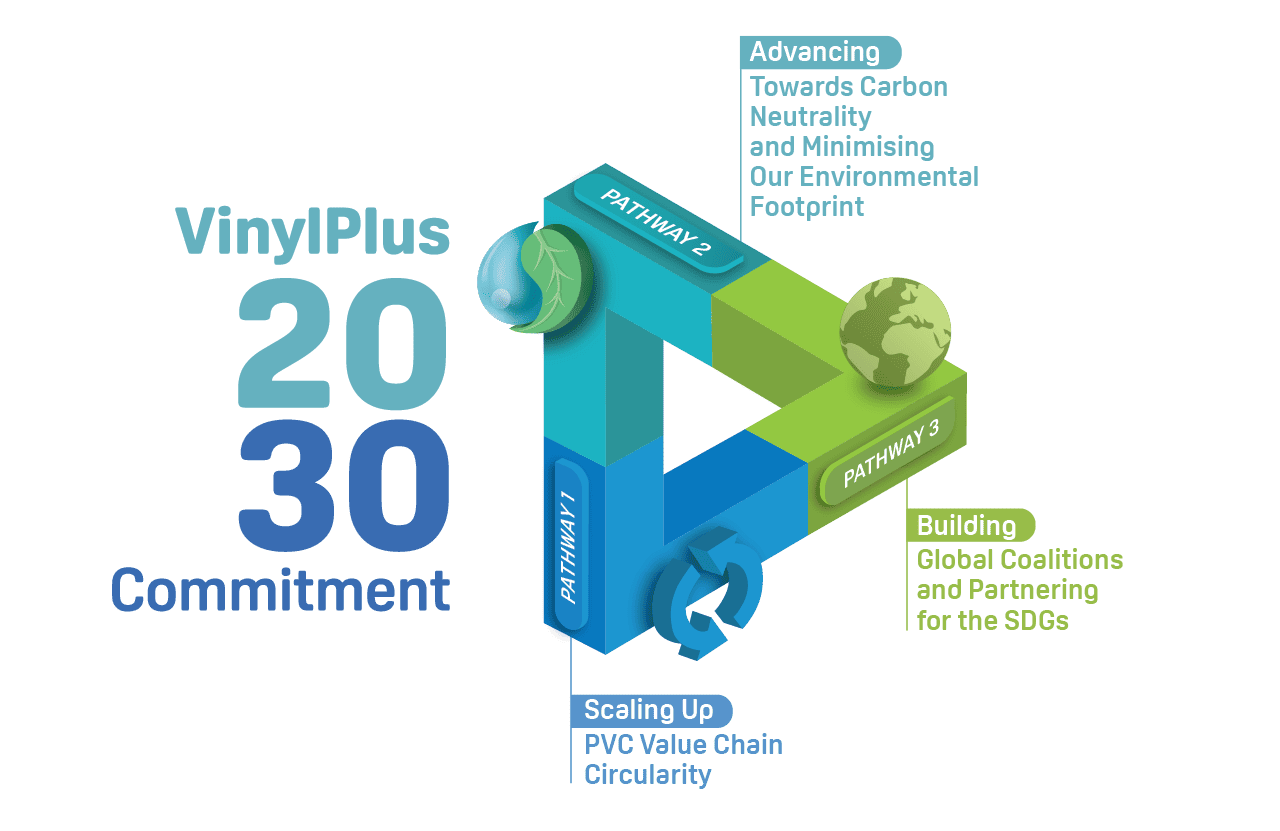

The European PVC industry is committed to sustainable development. This is put into practice by VinylPlus®, which encompasses the whole value chain: resin producers, additive producers, plastics converters, and recyclers.

The VinylPlus 2030 Commitment has been developed bottom-up through industry workshops and with an open process of stakeholder consultation. Three Pathways and 12 Action Areas have been identified embracing the PVC value chain’s circularity, its advancement towards carbon neutrality, minimisation of the environmental footprint of the PVC production and products, and its engagement with stakeholders and global coalitions.

The regional scope of the programme is the EU-27 plus UK, Norway and Switzerland.

The founding members of VinylPlus are The European Council of Vinyl Manufacturers (ECVM), European Stabiliser Producers Association (ESPA), European Plastics Converters (EuPC) and European Plasticisers.

The progress is monitored by an independent Monitoring Committee and documented by yearly Progress Reports that are independently audited and verified by third parties. The praise for the VinylPlus programme comes from a wide range of stakeholders, e.g. the European Commission which considers VinylPlus a frontrunner for circular economy.

VinylPlus has committed to recycle 900,000 t/year of PVC as part of the EU Circular Plastics Alliance. VinylPlus is registered as a partnership on the UN Partnerships for SDGs platform.

"VinylPlus can be considered a frontrunner for the circular economy"

Gwenole Cozigou, Director, DG Growth, European Commission