The critical role of packaging in the pharmaceutical industry cannot be overstated. It safeguards the integrity of medicines, ensures their safe delivery to patients, and significantly impacts their shelf life. In Europe, blister packaging is preferred, with rigid PVC (polyvinyl chloride) as the most used base material.

Why PVC-based packaging dominates the pharmaceutical sector

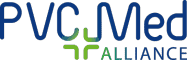

PVC alone or in combination with polyvinylidene chloride (PVDC), aluminium, chlorotrifluoroethylene (CTFE), or oriented polyamide nylon (OPA) holds a market share of almost 100% in medical blister packaging. There are several reasons for this dominance:

Low permability

High safety

Excellent thermoformability

Compatibility with other materials

Cost-efficiency

Recyclability

Environmental advantages of PVC blister packaging

Medication delivery differs between the regions of the world. In Europe, for instance, around 80% of all pharmaceutical oral solid dosages are delivered in blister packs, whereas bottles are preferred in the United States. It is well established that blister packaging offer several benefits in terms of contamination avoidance, correct dosing, improved child safety and senior friendliness.

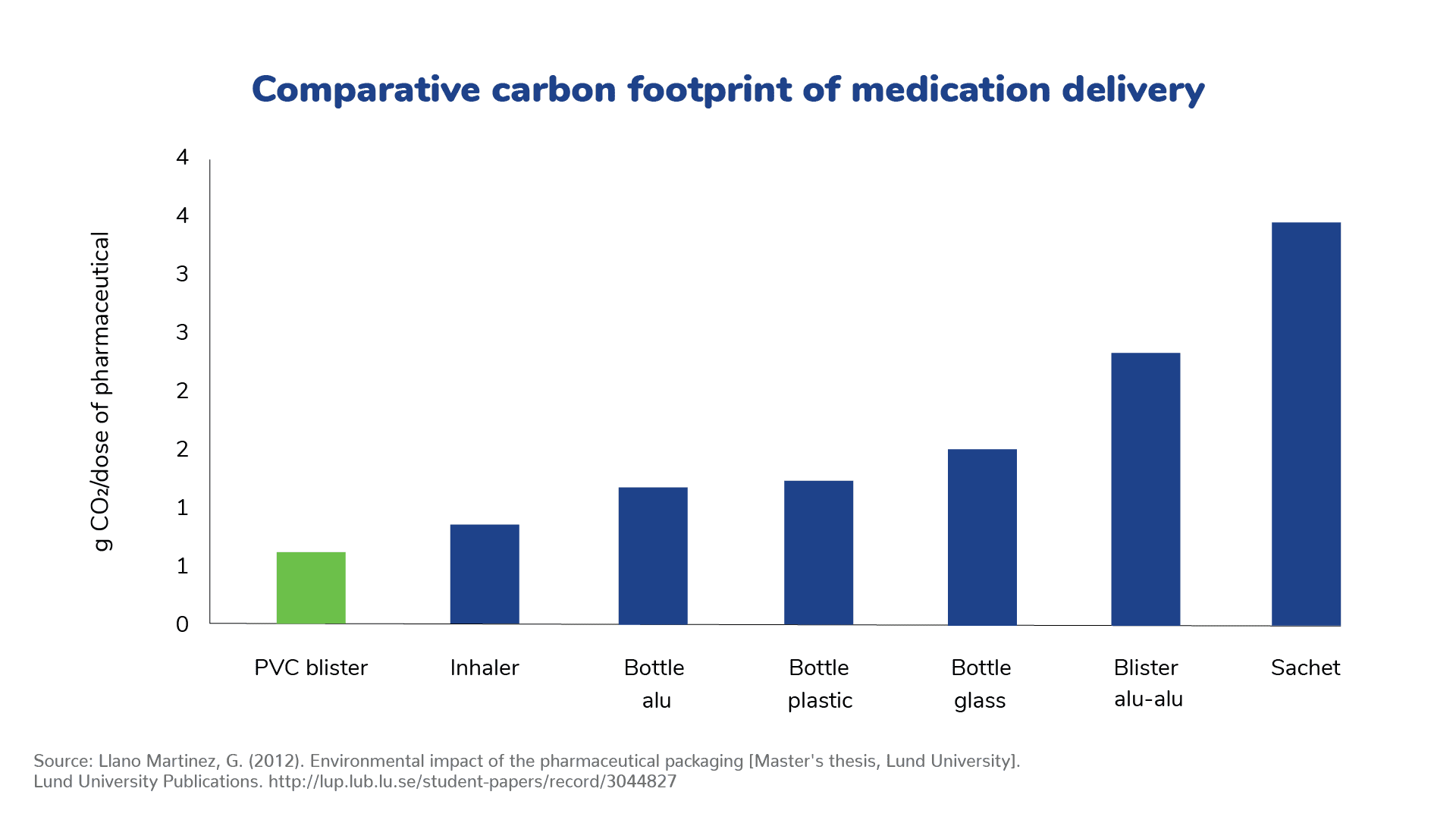

When choosing PVC as the base material for blisters, the climate also benefits. Studies show PVC has a low carbon footprint compared to alternatives:

- PVC blisters had the lowest climate impact compared to alu/alu blisters, aluminium bottles, glass bottles, plastic bottles, inhalers, and satchets.

- The climate impact of satchets is almost 4x higher than PVC.

Pedrosa de Oliveira et al. (2021)

- Found that "aluminum is more harmful to the environment than PVC, due to the high emission of CO₂ during its production."

- In their life cycle assessment of three types of pharmaceutical packaging (blisters, bottles, and satchets) for four different medications, the authors found that "PVC is the forming film that presented the lowest environmental impacts, followed by PVC/PVDC and OPA/Alu/PVC."

- Across all four scenarios, PVC-based solutions have the least impact on global warming, abiotic depletion, acidification, ozone depletion, and eutrophication.

- For bottles, HDPE bottles with PP caps and brown glass bottles with PP caps were chosen, while paper/alu/PE and alu/resin were chosen for satchets.

PVC blister packaging in a circular economy

Leading PVC film manufacturers, recyclers and VinylPlus have come together in the joint project VinylPlus PharmPack for the sustainable development of PVC pharma blisters packaging. The aim is to demonstrate the recyclability and sustainability of pharma blisters made of aluminium and PVC in the context of the European Packaging Directive 94/62/EG and national laws.

Several small-scale tests for the separation of PVC from aluminium have been successfully carried out by Fraunhofer IVV. Laboratory tests carried out on the produced recyclates at Perlen Packaging and Liveo Research yielded promising results. Larger-scale trials have been scheduled at Fraunhofer IVV, following the installation of a dedicated pilot plant. The rPVC produced in the pilot plant will then be further tested by Perlen and Liveo to verify whether the quality obtained is suitable for use in new products.

PVC has the lowest cost per dose of medicine

PVC blister packaging, made from cost-efficient PVC resin, offers the lowest cost per dose of medicine. In contrast, solutions predominantly using aluminium, such as OPA/aluminium/PVC, are nearly three times more expensive than packaging made entirely from PVC.