Anesthetic and oxygen masks rank among the most frequently utilised medical products. PVC stands out as the optimal material for these masks, offering distinct advantages in anesthesia and oxygen delivery. The transparency of PVC ensures excellent visibility, enhancing patient safety significantly. Additionally, the unmatched softness of PVC contributes to patient comfort during use.

A unique feature of PVC plastic is its versatility, as it is the only polymer that can be formulated to be both rigid and flexible. This adaptability enables the production of masks using a single polymer, simplifying the mechanical recycling process and making PVC-based masks a more sustainable choice in medical applications.

Applications of PVC face masks

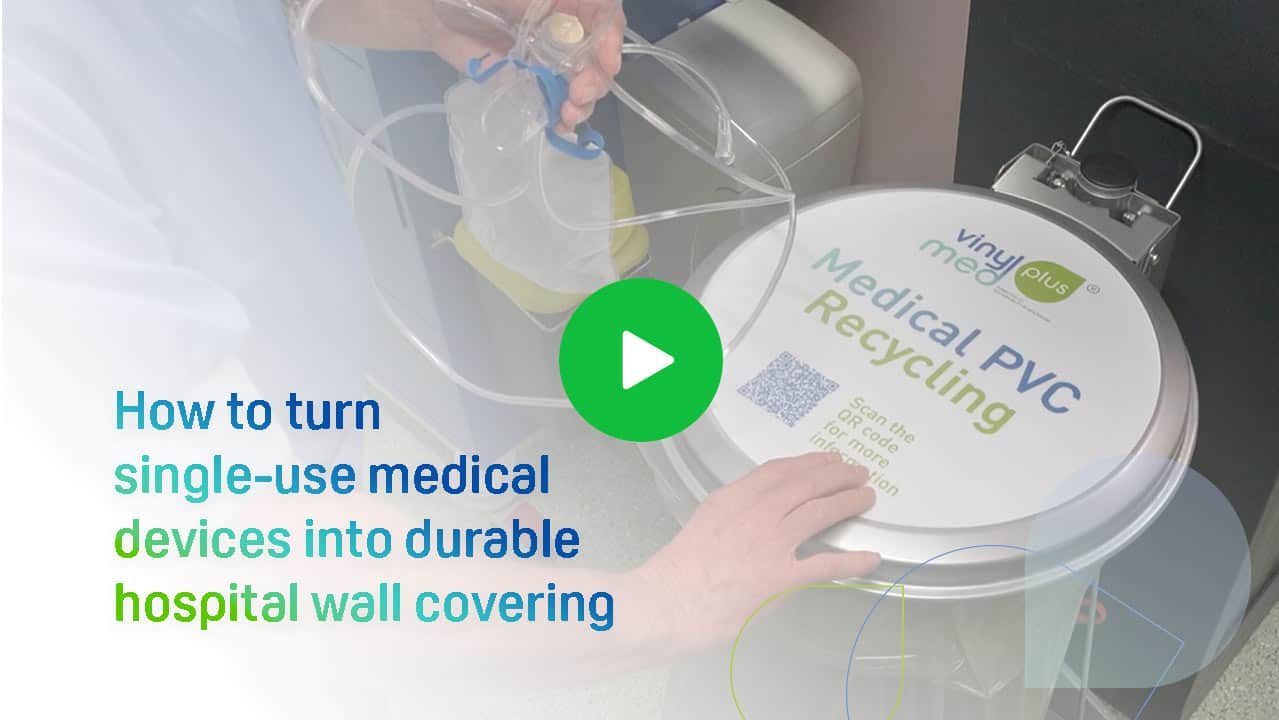

PVC anesthetic and oxygen masks in the circular economy

PVC anesthetic and oxygen masks, collected at VinylPlus® Med hospitals, are prime candidates for mechanical recycling. This process aligns with the commitment to sustainability and responsible waste management in the healthcare sector. The high-quality, colorless medical PVC waste from these masks undergoes a transformation into a variety of useful products such as durable hospital wall covering, demonstrating the versatility and recyclability of PVC in medical applications.

An important aspect of this recycling process is the medical PVC value chain's proactive shift away from DEHP and other low molecular weight (LMW) phthalates. This commitment not only enhances patient and staff safety but also contributes to the broader goal of sustainable healthcare practices.